VIP member

Product details

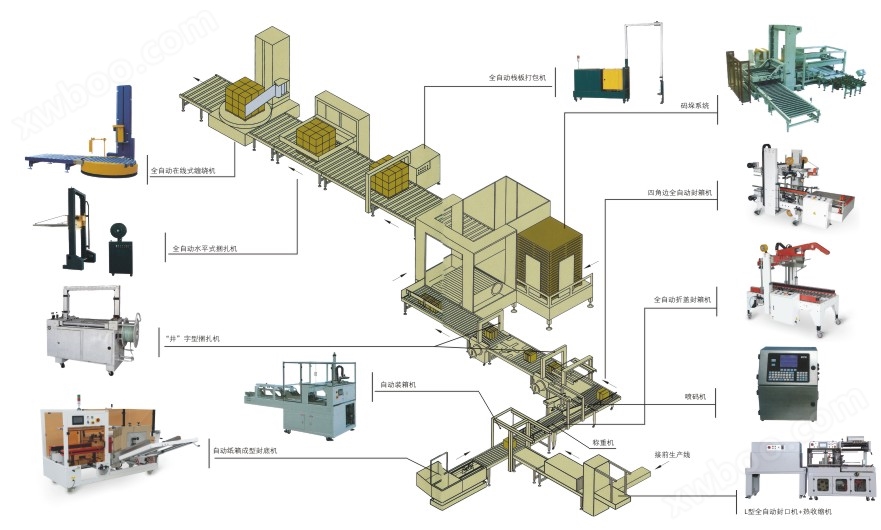

The application of robots in finished product palletizing is becoming increasingly widespread and recognized by the market. It has advantages that other equipment cannot compare to, and in recent years, it has developed in Europe, America, Japan, and other countriesThe application of palletizing robots in the country has exceeded 70%, and they are mainly designed for packaging applications,Stacking robot armAlthough the body is compact and can be integrated into compact packaging machinery, it can still meet your needsAll requirements regarding reach distance and payload. Combined with motion control and tracking performance, the robot palletizer is highly suitable for application in flexible packaging systems, greatly reducing the packaging timeInstallation cycle time. With good accuracy and professional conveyor tracking performance,Stacking robot armWhether it is a fixed position operation or a motion operation, its picking and placing accuracy is standard.

Small size and fast speed, optimized specifically for packaging applications, are the inevitable choice for robot automation. Equipped with a complete set of auxiliary equipment (from integrated air and signal system)It can be equipped with packaging software and has simple mechanical integration. Programming is also very convenient. In terms of efficiency, palletizing robots can not only bear high loads,And the speed and quality are much higher than manual labor.

At present, taking the four axis handling robot as an example, it is divided into various models ranging from 100Kg to 700Kg according to different loads. It can achieve a fast speed of 2500mm/s during linear motionMoving speed; The handling capacity can reach 1600 times per hour with high energy. In terms of accuracy, each palletizing robot has an independent control system to ensure operational precision,And the repeatability accuracy can reach ± 0.5mm, which can fully meet the positioning requirements of logistics palletizing operations. Adopting advanced 4-axis design, with a reach distance of 3.15m and an effective weight of 250kgThe high-speed robot with load is very suitable for automatic stacking of materials in the form of bags, boxes, Flat noodles, bottles and other packaging forms. Suitable for harsh environmental applications, with a protection level of IP67.

The universality, reach distance, and load-bearing capacity of robots can almost meet the requirements of any stacking application. Although the initial investment for palletizing robots is relatively high, they can still reach the edgeCost effectiveness is maximized, and various robots are controlling costs for customers in terms of product stability. Currently, advanced palletizing robots have reached 5 and 6 axes,Through corresponding scientific and reasonable rigid mechanical body design, the robot body not only adapts to high load and high-frequency palletizing operations, but also in terms of control network, the palletizing machineRobot humans can communicate through "point-to-point" communication, as well as through different international standard bus interfaces (such as CC Link, PROFIBUS, Device Net, etc.) or throughEthernet enables convenient, fast, and reliable exchange of signals and data with peripheral devices and upper computers, achieving on-site networked control; It can also be programmed through software to set andFlexibly optimize different motion paths to meet the handling requirements of different production product models on site.

And through the communication methods introduced above, remote control of production can be achieved. Greatly improve efficiency and reduce costs; In terms of cost control, new technologies are constantly being added to the machinesTechnological achievements. For example, by using 2D (2D plane) and 3D (3D stereoscopic laser) vision systems, robots can automatically recognize the position of the grabbed object, enabling palletizingThe industry is more flexible, reducing the cost expenditure of product conveyor positioning equipment and manpower.Stacking robot armSpecially suitable for cardboard boxes in industries such as food, beverages, daily chemicals, cigarettes, alcohol, and pharmaceuticalsAutomated palletizing requirements for packaging and turnover basket packaging products.

In order to provide customers with comprehensive and thoughtful services and eliminate their worries. Our company has established a comprehensive after-sales service system and effective after-sales service

Service measures,And open it upProvide users with satisfactory answers to questions and technical support through a dedicated after-sales service hotline; And there is an after-sales service department to provide customers with

Regular follow-up visits. The company is currentlyHaving over ten membersAs a strong after-sales service team, professional after-sales service engineers provide guarantees for your after-sales service.

Our company provides the following repair services to youPromise and follow the dressWe promise to provide you with repair services in accordance with our requirements.

1、 One year limited warranty for the machine

From the date of your purchase (based on the official purchase date), the machine comes with a one-year free warranty (excluding vulnerable parts such as sealing knives, high-temperature adhesive tape, etc.).

2、 Service Hotline

Phone:

3、 After sales process

1. After the machine is successfully installed and debugged, the company enters the customer's file and dispatches professional after-sales service engineers to provide technical tracking services and regularly track the machine

Usage situation.After the machine reports a malfunction, you can call us by phone or notify our after-sales service department in writing. We will notify you within 1 hour of receiving the notification

I will contact you by phone firstProvide a detailed explanation of the cause of the malfunction and determine the time for on-site repairs. Additional fees will be charged for customers from other regions who come to the site.

2. When the after-sales service engineer comes to repair the machine, they first conduct a detailed inspection of the machine, then introduce the cause of the malfunction to you in detail, and then carry out the repair. The machine is repaired

After you confirmSign and confirm on the after-sales service worksheet after the repair is completed.

4、 Door to door repair time

Guangzhou, Shenzhen, Dongguan, Zhongshan, Foshan and other cities require on-site repairs within 24 hours, while areas outside the province require on-site repairs within 72 hours.

5、 Exemption from warranty obligations

For machine malfunctions, abnormal operation, or damage caused by the following reasons, our company does not assume free warranty obligations. Please choose paid services.

1. When your machine exceeds the warranty period;

2. You did not use and maintain the machine according to the instructions or caused damage by human error;

3. Natural disasters and other force majeure events such as earthquakes and fires.

In order to provide you with better after-sales service and protect your rights, Shenzhen Shuangcheng Intelligent Packaging Equipment Co., Ltd. welcomes your participation in our work

Supervision.

electricityWords:

netAddress: http://www.szscpack.com

groundsAddress: Building 3, Fubilen Dingfeng High tech Industrial Park, Songgang Avenue, Bao'an District, Shenzhen

Online inquiry